Forging Advantages: Why It Outperforms Casting and Machining

The advantage of forging is becoming increasingly important as industries demand higher strength, reliability, and performance. Unlike casting or machining, forging reshapes metal through controlled deformation, improving internal grain flow and mechanical properties. For OEM components that must operate under high stress, the advantages of forging process provide a measurable performance edge.

This article explains the key advantages of forging over machining and casting, how hot forging enhances part performance, and why forged components are preferred in automotive, energy, and heavy equipment applications.

What Is Metal Forging?

Forging is a metal forming process in which heated billets are pressed or hammered into shape. During deformation, the material grain structure realigns to match the part’s geometry, eliminating porosity and weak points.

There are several common forging methods:

- Open-die forging – For large shafts and rings

- Closed-die forging – For precision near-net-shape parts

- Hot forging – Performed above recrystallization temperature

- Cold forging – For high-volume fasteners and hardware

Whether manual or automated, the forging process produces components that are stronger than parts made by casting or machining alone.

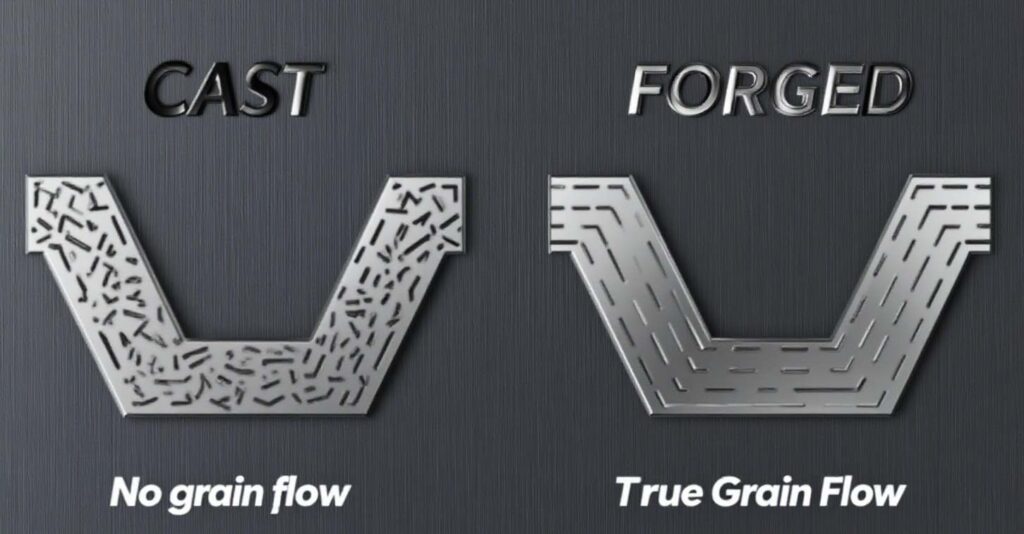

Key Advantages of Forging vs Casting

The most significant advantage of forging over casting is mechanical strength.

Aspect | Forging | Casting |

Internal integrity | Dense structure, no porosity | Porosity and shrinkage common |

Grain flow | Controlled directional grain | Random grain structure |

Mechanical properties | Higher tensile and fatigue strength | Lower impact resistance |

Reliability | Consistent performance | More variation between batches |

Why Forging Performs Better

- No internal voids → Better fatigue life

- Grain flow follows shape → Higher impact resistance

- Better structural consistency → Safer for critical parts

For safety-critical components—shafts, gears, flanges—cast parts are often rejected due to their lack of structural integrity.

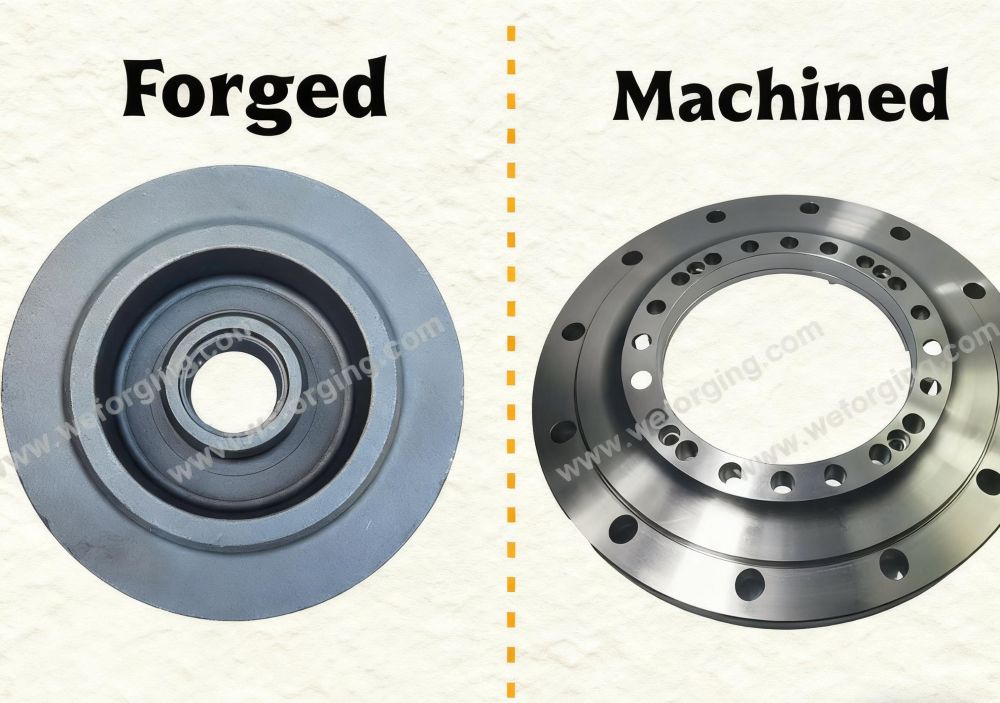

Advantages of Forging Over Machining

Machining removes material to shape a component. While machining achieves precision, it does not improve base material strength.

The advantages of forging over machining include:

✔ Superior strength-to-weight ratio

✔ Less material waste and better cost efficiency

✔ Improved fatigue performance in dynamic conditions

✔ Ability to withstand shock, torque, and pressure

In many industries, forged blanks are CNC machined to final dimensions — combining forging strength and machining precision in one component.

Read more about forged vs machined components

Advantages of Forging Process for OEM Applications

Across major industries, the advantages of forging process translate into measurable product reliability:

Industry | Forged Components | Performance Benefit |

Crankshafts, control arms | High impact & fatigue resistance | |

Wind energy | Turbine shafts, forged flanges | Load stability under cyclic stress |

Cylinder ends, piston rods | No porosity, leak-free sealing | |

Drill heads, gear hubs | Shock-load durability | |

Construction | Tie rod ends, steering knuckles | Safe under heavy mechanical load |

Why Forging Improves Material Performance

The advantage of forging is structural, not just dimensional:

- Grain flow alignment increases tensile strength

- Work hardening strengthens surface layer

- Deformation removes inclusions and internal defects

- Compatible with heat treatment for higher hardness

These characteristics cannot be achieved by casting or fully machined bar stock.

When Should You Choose Forging?

Choose forging when your application requires:

✔ High strength-to-weight ratio

✔ Zero porosity and structural integrity

✔ Reliable performance under load

✔ Long-term fatigue resistance

✔ Custom shapes with repeatable tolerance

If the part must not fail, forging is the correct choice.

Conclusion

The advantage of forging lies in its ability to produce stronger, safer, and more durable components than casting or machining alone. With better grain structure, mechanical strength, and fatigue resistance, forging remains the preferred process for critical industrial applications.

For OEM-grade forged components—shafts, flanges, gears, cylinder parts—selecting forged rather than cast or machined parts significantly improves performance and service life.

F.A.Q.

The main advantage of forging over casting is superior mechanical strength and reliability.

Forging produces dense, defect-free components with continuous grain flow, making them stronger and more fatigue-resistant than cast parts, which often contain porosity and shrinkage defects. For safety-critical applications such as shafts, gears, and flanges, forged parts offer better performance and longer service life.

Forging is better than machining when structural integrity and fatigue performance are required.

Machined components are cut from bar stock, which breaks grain flow and does not improve the base material. Forged components maintain directional grain structure and achieve higher strength-to-weight ratios, making them ideal for parts such as piston rods, crankshafts, and hydraulic cylinder components.

Industries such as automotive, wind power, mining, and heavy equipment benefit the most from the advantages of forging.

These sectors require durable components that can handle high stress, vibration, and cyclic load. Forged flanges, turbine shafts, bearing housings, and gear hubs are widely used due to their superior strength and reliability compared to cast or fully machined alternatives.